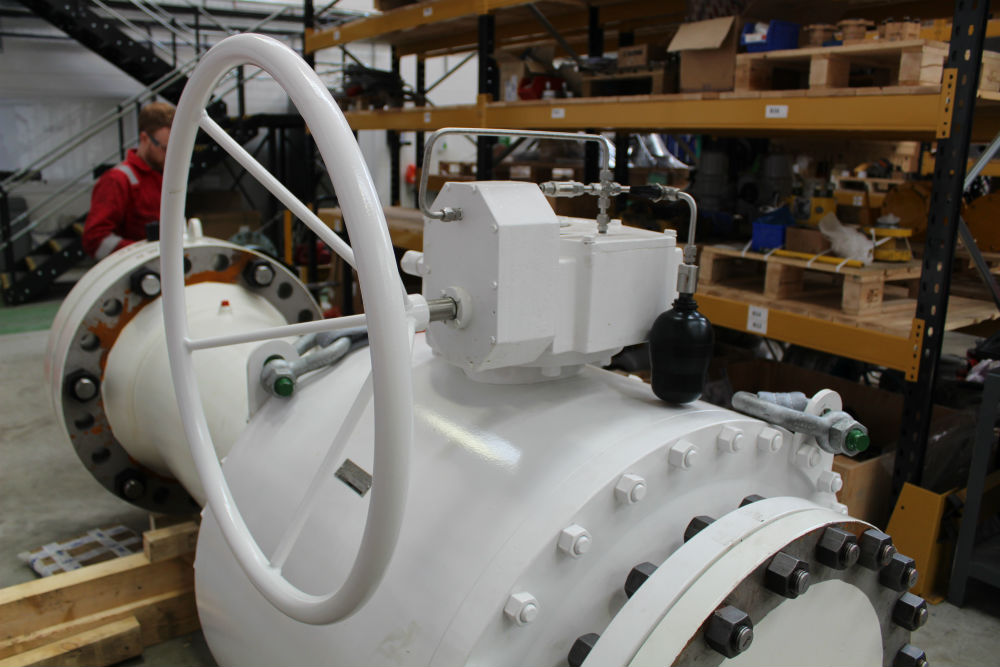

Subsea Modification to Topside Ball Valve

Modification to 24” 150# Ball Valve for Temporary Subsea Application

SVS was on hand to provide an effective Subsea engineering conversion solution of a Topside valve in order to meet a client's urgent lead time requirmeent, our valve engineers and engineering partners completed the full conversion of the valve in under 5 weeks.

Phase 1

• Full Strip & Inspection of Valve and Gearbox.

• Carry out QA & Dimensional Inspection of parts requiring modification.

• Model parts on CAD and carry out engineering review of valve to determine Subsea modifications required.

• Review of Gearbox to determine marinization feasibility.

• Full review of drive train.

• Redesign of existing sealing systems & identify additional ingress seals.

• Detailed manufacturing & modification drawings

• Machining of new components & modification to existing (Valve & Gearbox).

• Inclusion of bladder compensator to gearbox.

• Assembly of valve & gearbox.

• Conduct Witnessed API 6D FAT Programme

• Painted to Norsok M501 System 7

Phase 2

• Unitise with Class 150# → Class 900# Crossover Spool.

• Conduct 24hr + 1hr Open Body Test.

• Prepare for shipping.

Thanks to everyone involved in assisting with this accelerated delivery.